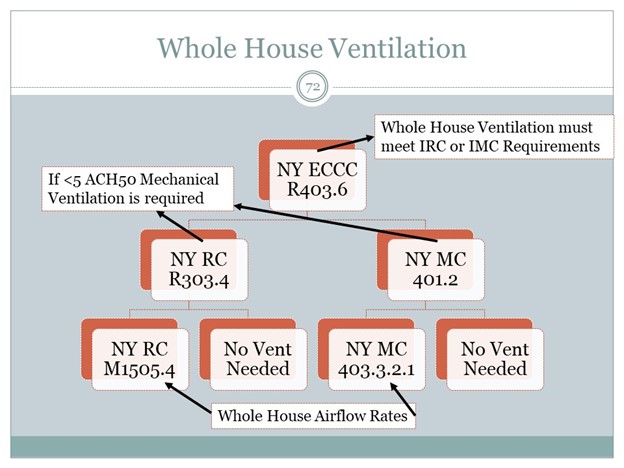

Did you know that whole house ventilation is REQUIRED by NYS Building Code for ALL single-family homes?

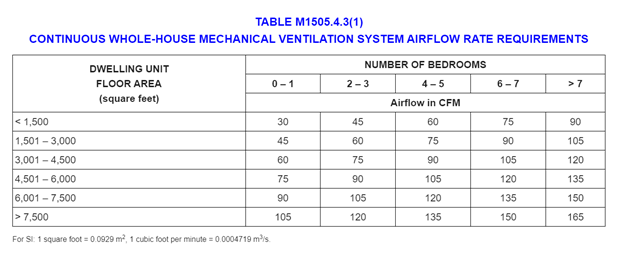

The whole house air flow rates are determined one of two ways:

OR

This formula: AirFlow in CFM = (0.01 x Floor Area) + ((7.5 x (Bedrooms +1))

There are a few different ways this can be achieved; some options are better than others…so lets get into it.

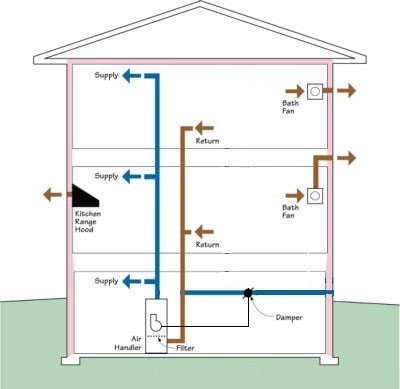

Exhaust Ventilation

$ – less expensive, ☹ – poor comfort and performance

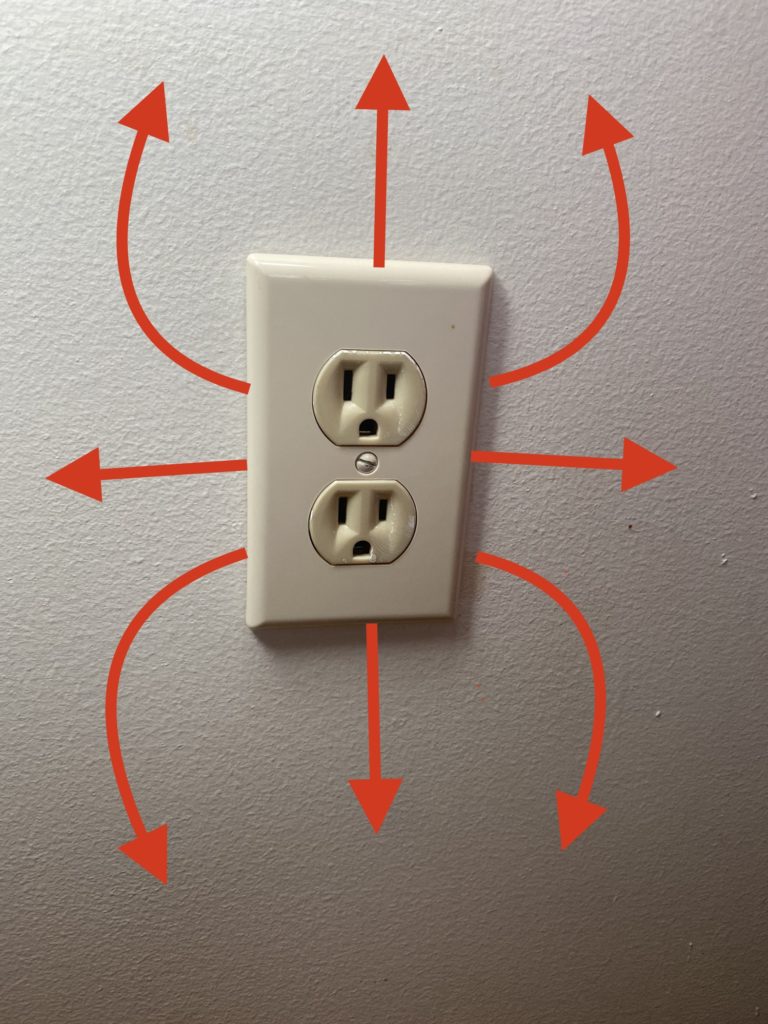

Your bathroom fan is a basic way to meet the ventilation requirement. When you take a shower, it’s doing double duty – removing moisture and pulling in outside air. The outside air pulled in comes from some nasty places like through the fiberglass in your walls and ceilings. After knowing this, you can imagine what this does to your indoor air quality because it’s hard to filter.

Bathroom fans should be running almost all day, every day (18 to 24 hr./day).

No one wants to listen to a noisy bath fan all the time, so manufacturers have made them very quiet. You can barely tell they are running sometimes. You’ll want to find one that’s under 1 sone for it to not be a nuisance and rated for continuous use.

Another option is to connect the bath fan switch to a motorized damper. Whenever the fan turns on, the damper opens and allows outdoor air in. This method is much better at controlling where and when outdoor air enters the building

Supply Ventilation

$ – less expensive, ☹ – poor comfort and performance

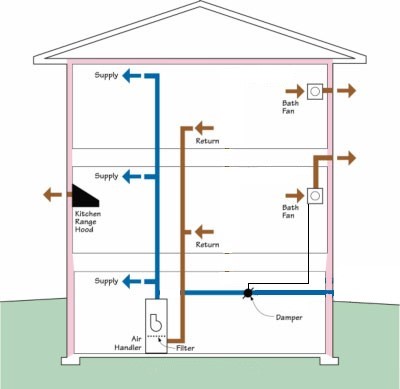

Supply ventilation is a bit trickier to execute properly. When you have supply ventilation, you are pressurizing the building and usually using the central furnace fan to pull in the air from a motorized or barometric damper. For this to work and be up to code, your furnace fan should be running all the time or run on a schedule. Most modern thermostats can control this operation. Remember the second law of thermodynamics? Pressure moves from areas of high pressure to low pressures. Imagine blowing up a balloon with a couple pin holes already in it. The blown in air would be exfiltrating (exiting) the balloon just like all the holes in your house. In a heating dominated climate, like Rochester NY, pushing hot air out of the building through exfiltration can cause condensation on surfaces you don’t want them to collect on. As a result, there’s an increased chance for mold and mildew to start growing – not good! The pressures introduced through supply air ventilation are around 2pa-5pa with reference to outside (around .01 inches of water column). It’s common to see these on standard code built houses today and an affordable way to introduce fresh air in an existing home.

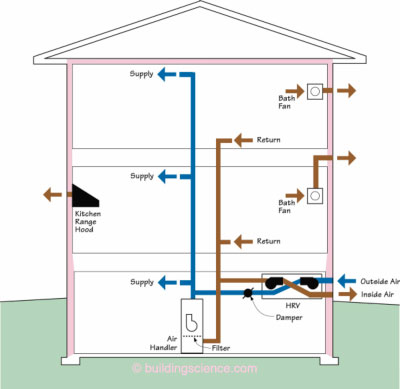

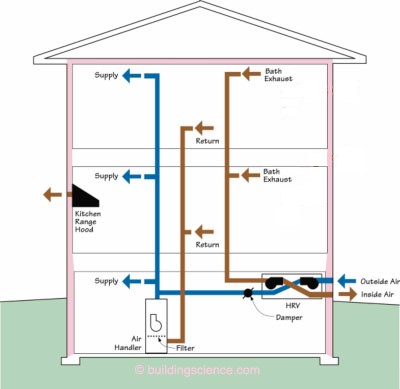

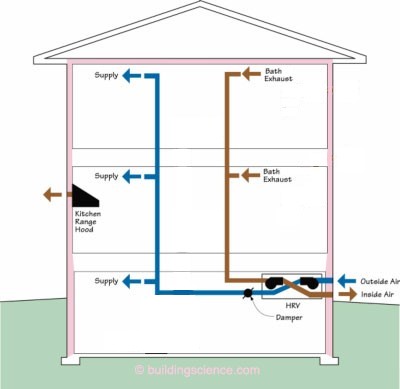

Balanced Ventilation

$$ – More expensive, Best indoor air quality

We touched on balanced ventilation a bit when we showed the exhaust fan connected to a motorized damper but there wasn’t any balancing involved. Every CFM exhausting will be made up for through infiltration or planned supply ventilation. Whether it comes in through a duct or cracks in the building its going to be 1 CFM in = 1 CFM out. A balanced system will have control over the outdoor air coming in the building AND exiting. The outdoor air will have an opportunity to be filtered before it reaches the occupants breathing the air. A balanced ventilation system will supply and exhaust air at the same rate with one entrance point and one exit point, so the house is never under a positive or negative pressure. There are a few ways you can accomplish balanced ventilation, but it usually involves the same equipment – a Heat Recovery Ventilator (HRV) or an Enthalpy Recovery Ventilator (ERV).

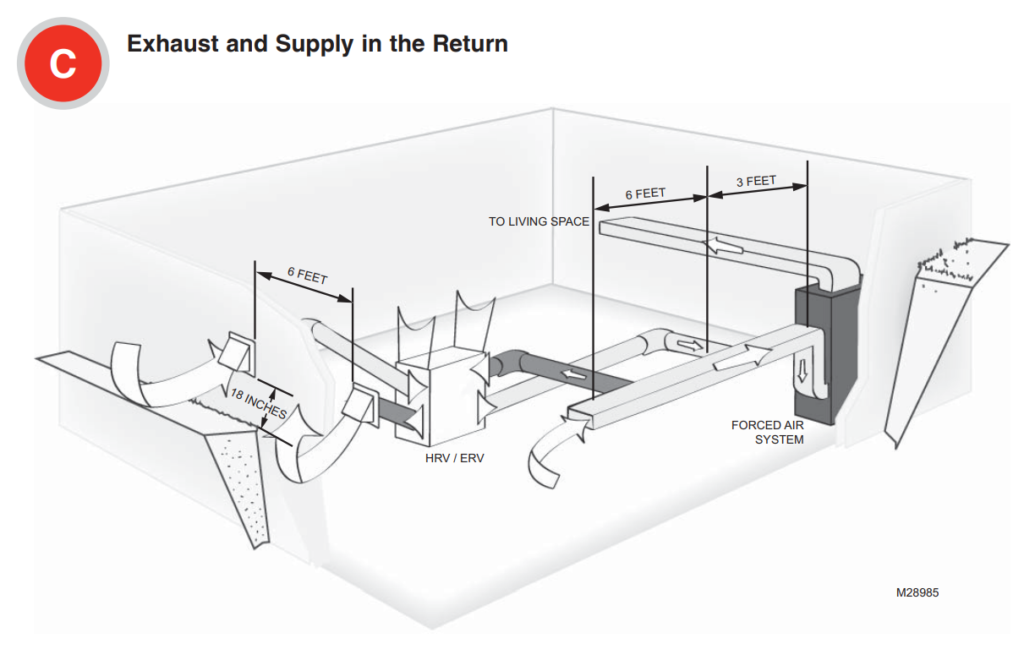

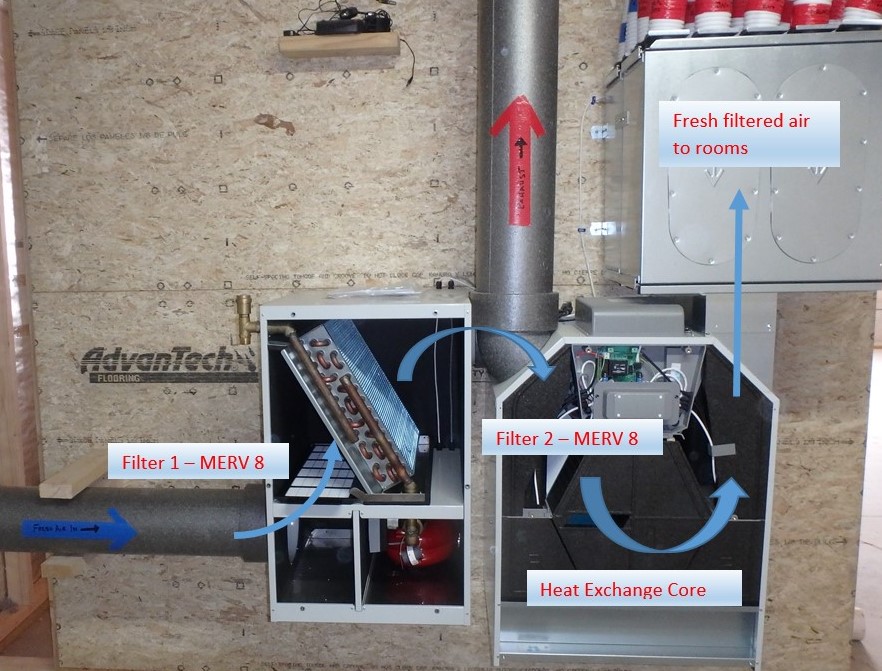

Both have insulated intake and exhaust ducts that go from outside to a box that look remarkably similar. Inside the box, there are filters to clean the air and a core that defines whether its and HRV or ERV. Its best to follow the manufactures specifications on where and how to pipe in the outdoor and extract air terminations.

Both cores allow for entering and exiting air streams to pass next to each other but not mix. While they are passing through the core, heat from the indoor air warms up the cold outside air and the opposite happens when you are cooling the space. An HRV core is made from a rigid plastic and allows only heat to transfer between streams. An ERV core is made of a paper like material which allows for heat and moisture into the incoming air stream.

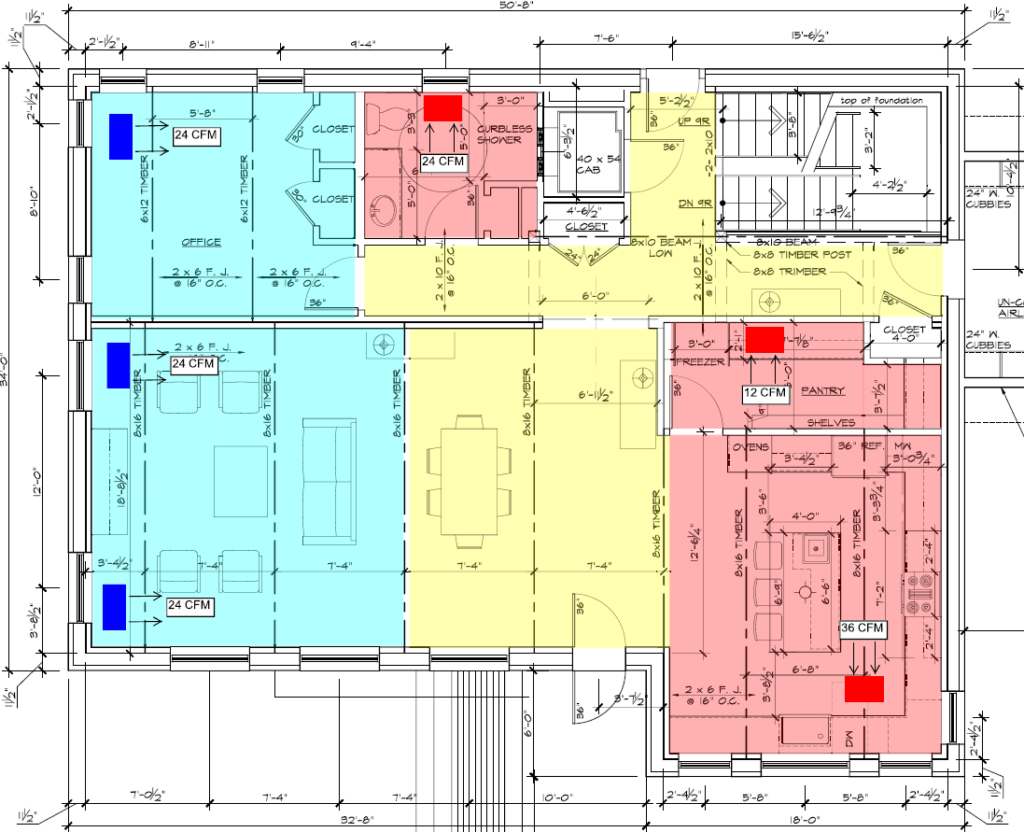

The ducts exit the box and have a couple different options of where they can go. On new buildings its best to have dedicated supply and extract air ducts. You want to extract air from kitchens, bathrooms and utility rooms and supply fresh air to bedrooms and living rooms. In a retrofit situation, its easiest to tap into the duct system.

Passive House Ventilation

$$$ – Designed and Commissioned Whole House Ventilation

The Passive House Standard is 1st and foremost a Comfort Standard. We must ensure that Thermal Comfort is maintained at all times. When ventilating a house to passive house standards we are faced with a few other considerations.

- Very High Heat Recovery Efficiency – this ensures the temperature being supplied to the rooms of the house is always above 65 F, even when it is really cold outside

- Very Quiet Operation – We all know how important a quiet building is. Usually it is why we don’t run the baths fans when we should, or run the kitchen range hood, or build a house next to a quarry. It’s too noisy! The ventilation system for a passive house must be nearly silent (under 35dBA)

- High Levels of Filtration – Indoor Air Quality is critical for comfort. We want to achieve at least MERV 13 levels of filtration, with most systems allowing for higher levels.

- Low Energy Use – Typically the systems run on a little less than 30 watts to operate

- Systems tested for Cross Leakage – Passive House Ventilation system are tested to ensure there is no leakage between the 2 streams of air.

- Full Ventilation System design and commissioning – not only do we design the system to deliver a given amount of air to a room, but we them commission the system to ensure it is delivering the correct amounts of air to the rooms.

Nice explanation Matt, thanks! I’d like to know more about the difference between ERV and HRV and how HRV can help with humidity control.

Gary, Great Question! Heat Recovery Ventilators (HRV) will only recover sensible heat. An Energy Recovery Ventilator (ERV) will recover both sensible heat and latent energy. Generally speaking the HRV will have a higher sensible heat recovery rate, than the ERV, however because the ERV is also recovering some moisture, the total energy recovery is usually a little higher with the ERV.

In our climate we almost always recommend an ERV.

In the winter the ERV will help keep the moisture inside the house.

In the summer, after you have paid to cool and dehumidify the air in the house, the ERV will help keep the warm humid outdoor air out of the house.

Keep in mind that while the ERV help maintain the humidity inside the house (compared to an HRV), the best systems in the world only recover about 70% of the humidity, so over ventilating will result in overly dry air in the winter.